DIACOMP® PLUS HP

Polishing System for Composite, Hybrid Ceramic, 3D Printed Hybrid Material

Diamond Impregnated Polishing System

Diamond Impregnated Polishing System- Diamond grit for highest efficiency

- Polishers specifically adapted to each processing step

- Best results even on very hard composites

Curion is proud to be an authorized distributor of EVE Ernst Vetter products in Canada. This product is backed by the manufacturer's warranty.

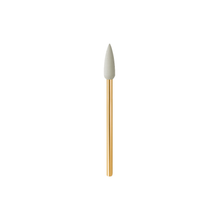

| Item No. | 6142 / 6242 |

| Dimensions (mm) | 4 x 13 | |

| Packaging unit | 1 | |

| RPM (min-1) | 3.000 - 8.000 | |

| RPM max. (min-1) | 20.000 | |

| Packaging | Refill | |

| Shape | Flame | |

| Grit | Medium / Fine | |

| Polishing level | Pre-polishing / High-shine polishing | |

| Area of use | 3D Printing Hybrid Material, Hybrid Ceramic, Composite |

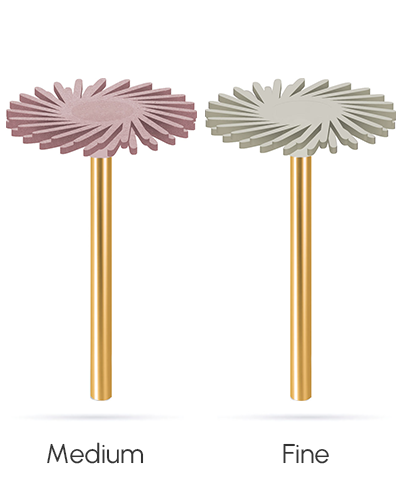

| Item No. | 6148 / 6248 |

| Dimensions (mm) | 11 × 2 | |

| Packaging unit | 1 | |

| RPM (min-1) | 3.000 - 8.000 | |

| RPM max. (min-1) | 20.000 | |

| Packaging | Refill | |

| Shape | Wheel | |

| Grit | Medium / Fine | |

| Polishing level | Pre-polishing / High-shine polishing | |

| Area of use | 3D Printing Hybrid Material, Hybrid Ceramic, Composite |

| Item No. | 6100 / 6200 |

| Dimensions (mm) | 26 x 2,5 | |

| Packaging unit | 1 | |

| RPM (min-1) | 3.000 - 8.000 | |

| RPM max. (min-1) | 20.000 | |

| Diamond impregnated | Yes | |

| Packaging | Refill | |

| Shape | Lense | |

| Grit | Medium | |

| Polishing level | Pre-polishing | |

| Area of use | 3D Printing Hybrid Material, Hybrid Ceramic, Composite |

| Item No. | 6157 / 6257 |

| Dimensions (mm) | 17 × 1,6 | |

| Packaging unit | 1 | |

| RPM (min-1) | 3.000 - 8.000 | |

| RPM max. (min-1) | 20.000 | |

| Diamond impregnated | Yes | |

| Packaging | Refill | |

| Shape | TWIST | |

| Grit | Medium / Fine | |

| Polishing level | Pre-polishing / High-shine polishing | |

| Area of use | 3D Printing Hybrid Material, Hybrid Ceramic, Composite |

| Item No. | 6166 / 6266 |

| Dimensions (mm) | 26 × 2 | |

| Packaging unit | 1 | |

| RPM (min-1) | 3.000 - 8.000 | |

| RPM max. (min-1) | 20.000 | |

| Diamond impregnated | Yes | |

| Packaging | Refill | |

| Shape | TWIST | |

| Grit | Medium / Fine | |

| Polishing level | Pre-polishing / High-shine polishing | |

| Area of use | 3D Printing Hybrid Material, Hybrid Ceramic, Composite |

|  |  |

Frequently Asked Questions

Polishers should be used in slightly circular movements on the processed surface. This way indentations are avoided and a uniform polishing result is achieved.

The lifetime of individual grinders and polishers is significantly determined by the initial roughness, the size and the hardness of the processed surface. Also the adherence to the recommended rotation speed and the applied contact pressure play a decisive role on durability. Due to the variety of influencing factors it is not possible to define an exact number of applications per item.

Generally polishers must be discarded before the working part of the polisher is completely worn out and the mandrel in the grinder and polisher can be seen. Damaged or deformed instruments must be discarded immediately.

Please follow the application and safety precautions in order to achieve the best possible durability. View in Instructions/SDS tab.

No. The best polishing results are achieved when adhering to the recommended rotation speed. Excessive speed reduces the lifetime of the grinder or polisher and increases the heat development within the processed material. Depending on the area of application this may damage the processed material or when applied intraorally harm the patient.

Information regarding the rotation speed can be found on the packaging of every product and in the product catalogue. The maximum permitted rotation speed may not be exceeded.

Yes. For the best possible polishing result it is essential to use all steps of the polishing system. Processed surfaces should first be smoothened and subsequently be polished to high-shine. Depending on the system and the material the process is divided in steps.

In case individual steps are neglected surface defects may remain visible or the best possible polishing result is not achieved. In dentistry, surfaces that are not perfectly polished are a basis for bacteria or other contaminations.

Water cooling is only necessary when products are applied intraorally. The water cooling does not support the polishing process, but reduces the risk of overheating the processed material and therefore protects the patient. EVE suggests water spray cooling (at least 50 ml/min).

Find detailed information regarding the application of EVE grinding and polishing system in the application and safety precautions. View in Instructions/SDS tab.

No. All grinders and polishers are already impregnated with abrasive material. This means that abrasive grit is embedded in the binding material and provides the basis for material removal on the processed surface. Bringing additional abrasive into the process through polishing paste is not necessary and not useful.

Only exception are prophy cups PROPHY PLUS, PROPHY TWIST or the polishing brushes UNIBRUSH. These are specifically designed for the use with polishing paste.

Yes. Grinding and polishing instruments for intraoral application (RA/FG) are delivered non-sterile and need to be sterilised before first use. Even products marked as single-use need to be sterilised before their use.

Indications on the reprocessing process are available in Instructions/SDS tab.

Grinding and polishing instruments for intraoral application (RA/FG) that are not marked as single-use may be used again after reprocessing. The validated preparation and reprocessing instructions are available in Instructions/SDS tab.

Polishers marked as single-use must be sterilised once before their application. After application these items need to be discarded.

Exact information on the reprocessing of grinders and polishers is available in Instructions/SDS tab.

Generally disinfectants must be clearly marked as suitable for the reprocessing of polishing instruments. Often manufacturers use the term “rubber polishers”. It is moreover essential to follow the product specific indications related to concentration and application time of the disinfectant as this has a significant influence on the durability of grinding and polishing instruments.

All EVE shanks and mandrels have a diameter of 2,35 mm (HP/RA) or 1,6 mm (FG) and can be used in standard handpieces and contra-angle attachments. It must be ensured that these are in perfect technical and hygienical conditions and that they are well maintained.